ACE Injection Moulding Co., Ltd is a manufacturing company located in Dongguan City, which is one of the major industrial cities and manufacturing centers in Guangdong province, China. The company was established in 2006 by a group of professionals with over 20 years of experience in the plastic injection moulding industry. ACE Injection Moulding Co., Ltd has been an expert in the injection moulding business ever since.

In the plastic injection moulding industry, reducing mold cycle times is essential to increase job profitability. This is where the use of simulation technology comes into play. By using simulation technology, manufacturers can predict injection mold cycle times, which allows them to explore ways to reduce mold cycle times and ultimately increase job profitability. This is one area where ACE Injection Moulding Co., Ltd has expertise.

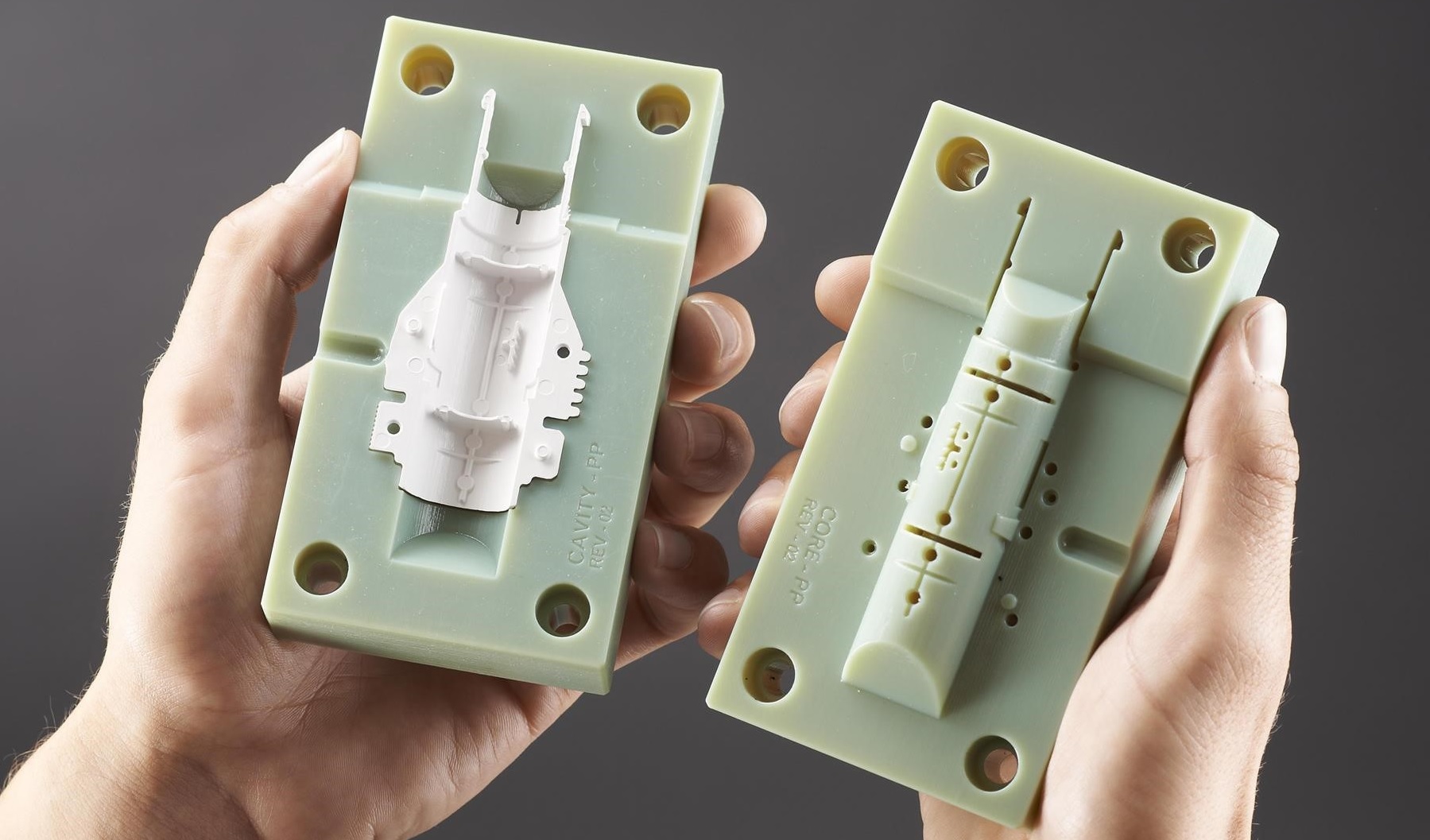

The process of injection moulding involves the melting of plastic pellets and injecting them into a mould to take a particular form or shape. This process usually takes some time, known as the mould cycle time. During this period, the product is molten and then allowed to cool before it is ejected from the mould. The duration of the mould cycle time depends on several factors such as the plastic material used, mould design, and injection moulding machine parameters.

To optimize the mould cycle time, ACE Injection Moulding Co., Ltd uses simulation software that is capable of imitating the entire injection moulding process, from the melting of the plastic pellets to the ejection of the final product. This software is used to generate a model that predicts the time it will take to complete the injection moulding process.

ACE Injection Moulding Co., Ltd uses injection moulding simulation software to perform various analyses, including the filling analysis, cooling analysis, and warpage analysis. The filling analysis checks whether the plastic is filling the mould properly, while the cooling analysis evaluates the time it takes for the product to cool down to a specific temperature range. The warpage analysis evaluates whether the part is bending, twisting, or cracking during the injection moulding process.

By performing these analyses with the injection moulding simulation software, the ACE Injection Moulding Co., Ltd team can determine the best design, material, and machine settings for each product. This means that they can optimize the mould cycle time, reduce waste, and ultimately save production costs. Additionally, these simulations allow the team to identify potential problems or defects in the final product and fix them before production begins, which saves even more time and money.

Reducing the mould cycle time is essential for businesses, as it leads to an increase in job profitability. When mould cycle times are reduced, more products can be produced within a shorter period, and the manufacturing process can proceed faster. This also leads to an increased capacity for producing more products, which can drive more sales and revenue.

In addition to reducing mould cycle times, ACE Injection Moulding Co., Ltd offers other services such as custom injection moulding, plastic injection mould design and manufacturing, and product assembly. The company has a team of experienced professionals that are dedicated to providing high-quality products and services to their clients. They ensure that each product meets the necessary requirements and specifications, and that they are delivered on time and within budget.

In conclusion, ACE Injection Moulding Co., Ltd is an industry expert in injection moulding, with a focus on reducing mould cycle times. By using injection moulding simulation software, the company can optimize mould cycle times, reduce waste, save production costs, and ultimately increase job profitability. With its team of dedicated professionals, ACE Injection Moulding Co., Ltd is committed to providing high-quality products and services to its clients.