Possible article:

China's plastic injection molding industry adapts to challenges

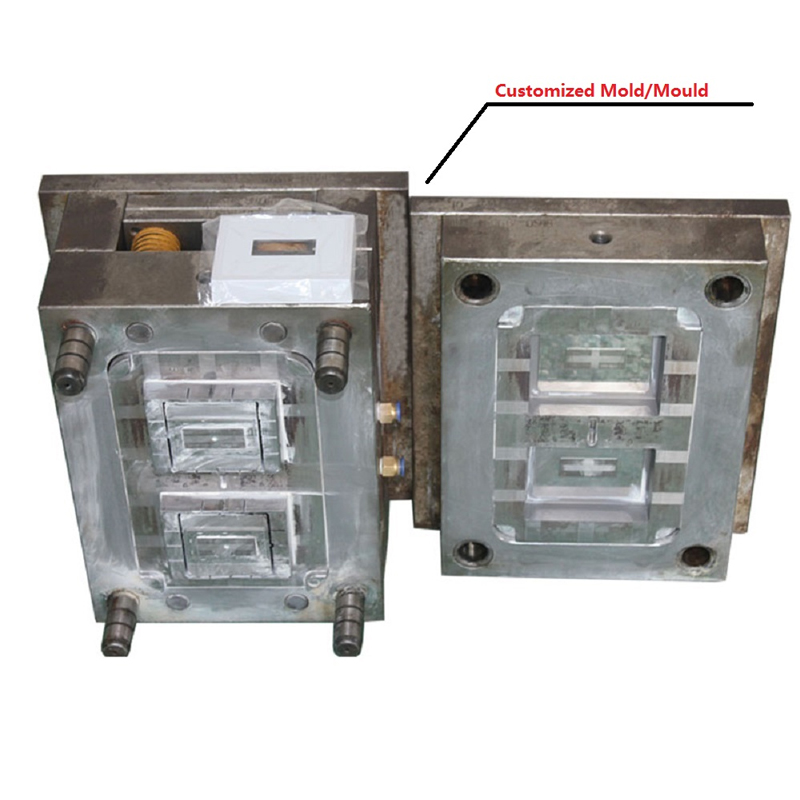

Plastic injection molding is a crucial manufacturing process that uses molten plastic to create complex and precise parts for various industries, such as automotive, consumer electronics, medical devices, and toys. In recent years, China has become a dominant player in this field, thanks to its abundant resources, skilled workers, and competitive costs. However, the industry also faces some challenges, ranging from quality control to innovation, that require continuous improvements and collaborations.

According to a recent market report, the global plastic injection molding market size was valued at $326.14 billion in 2019 and is expected to reach $529.1 billion by 2027, growing at a compound annual growth rate of 6.0% from 2020 to 2027. The Asia Pacific region, including China, is projected to account for the largest market share and grow at the fastest pace, driven by increasing demand for lightweight and durable components in various sectors. As such, Chinese plastic injection molding companies have been expanding their capacities and capabilities to meet the evolving needs of customers worldwide.

One of these companies is ACE Injection Moulding Co., Ltd., founded in 2006 by a group of professionals with more than 20 years of experience in the plastic injection molding industry. Located in Dongguan City, Guangdong province, ACE offers a wide range of services, including product design, mold making, injection molding, assembly, and packaging. The company's mission is to provide high-quality and cost-effective solutions to customers from diverse fields, such as automotive, electrical appliances, healthcare, and cosmetics.

ACE has achieved multiple certifications, such as ISO 9001:2015, ISO 14001:2015, IATF 16949:2016, and UL. These standards demonstrate ACE's commitment to quality, environmental protection, and customer satisfaction. The company has also invested in advanced technologies and equipment, such as 3D printing, CNC machining, EDM, and automatic assembly, to enhance its efficiency and productivity. Furthermore, ACE has a skilled workforce and a culture of continuous improvement, which allows it to adapt to changing market demands and customer preferences.

However, ACE and other Chinese plastic injection molding companies also face some challenges that require attention and action. One of the most significant challenges is quality control, especially when dealing with complex parts with tight tolerances and critical functions. Some Chinese factories have been criticized for using subpar materials, shortcuts, and outdated methods to cut costs, compromising the safety and reliability of the products. To overcome this challenge, ACE has established a rigorous quality control system that covers the entire production process from design to delivery, with multiple inspections and tests to ensure that every product meets or exceeds the customer's requirements and international standards.

Another challenge that ACE and other Chinese plastic injection molding companies face is innovation. While China has made remarkable progress in manufacturing and engineering, it still lags behind some developed countries in terms of originality, creativity, and intellectual property protection. Many Chinese companies are still relying on copying or imitating existing designs or technologies rather than developing new ones. To overcome this challenge, ACE has invested in research and development and collaborated with universities, research institutes, and customers to explore new materials, designs, and applications. ACE also encourages its employees to propose and implement improvement ideas and rewards the best ones.

Overall, the plastic injection molding industry in China is thriving and evolving, driven by the increasing demand for high-quality and cost-effective products from global customers. ACE Injection Moulding Co., Ltd. and other Chinese companies are at the forefront of this industry, providing innovative and reliable solutions to various challenges. While there are still some areas for improvement, such as quality control, innovation, and sustainability, Chinese plastic injection molding companies are well positioned to address them and contribute to the growth and prosperity of the industry and the society.