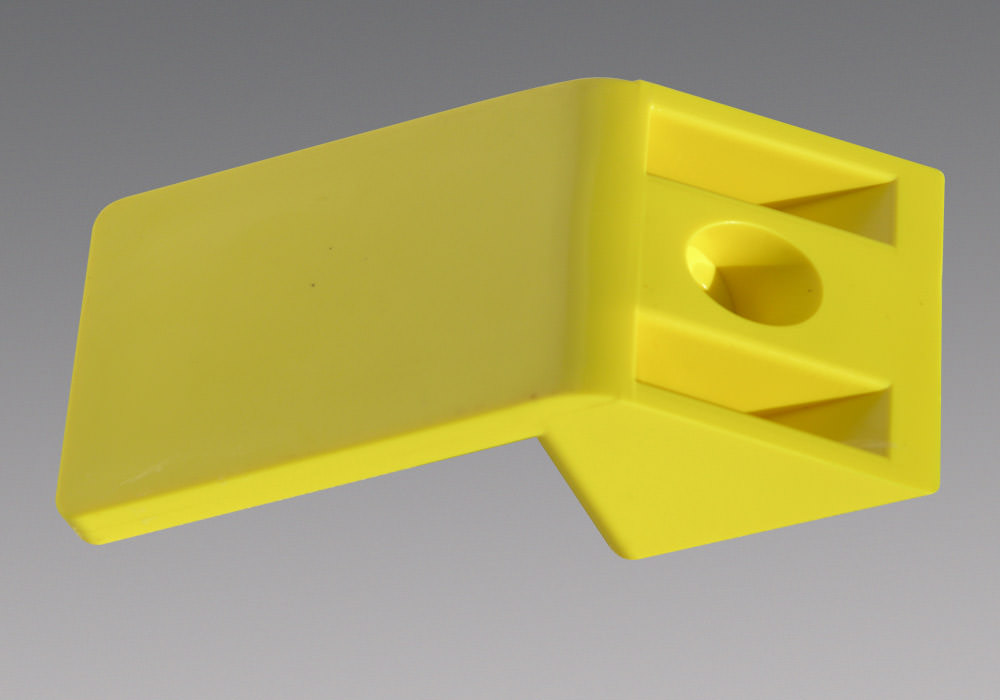

At Texas Injection Molding, our engineering group develops, documents, and monitors our production processes to ensure consistent and reliable part quality. With injection molding machines ranging from 55 tons to 825 U.S. tons and a maximum shot capacity of 115 oz., we can produce components using a variety of materials, including HDPE and ABS.

Among the different types of plastics, Polypropylene (PP) is an increasingly popular choice for injection molding applications. This thermoplastic polymer is known for its durability and chemical resistance, making it ideal for various product applications. PP injection molding is a highly versatile process that can produce parts of various shapes, sizes, and textures.

Some benefits of PP injection molding include:

1. Rapid and accurate production – PP injection molding is highly automated, resulting in rapid and accurate production of parts. This helps companies meet their production goals and deadlines.

2. Large production runs – PP injection molding can produce significant numbers of parts consistently, making it ideal for large-scale production runs.

3. Versatility – PP injection molding can produce parts of different shapes, sizes, and textures, making it highly versatile. This makes it ideal for a range of product applications.

4. Strength and durability – PP is highly durable and resistant to chemicals, making it ideal for manufacturing products where strength and durability are essential.

At Texas Injection Molding, our team of experts can help you with PP injection molding projects. We work collaboratively with our clients to develop custom solutions that meet their specific needs. Our state-of-the-art equipment and manufacturing processes ensure that our products are of high quality, reliable, and consistent.

Conclusion

Plastic injection molding is a versatile and reliable manufacturing process that can be used to produce high-quality components. At Texas Injection Molding, our engineering team has the experience and expertise to help our clients with various injection molding needs. From insert molding to PP injection molding, we have the knowledge and skills to deliver custom solutions that meet our clients' specific needs. Contact us today to learn more about our services and how we can help you with your next project.