Injection molding is a widely used manufacturing process for the production of plastic products. It is a process whereby molten plastic is injected into a mold cavity under high pressure and cooled to form a solid part. The injection molding industry has been growing rapidly over the years, and today it is one of the most important manufacturing processes in the world. There are many benefits of using injection molding components for the production of plastic parts, some of which include:

1. High Production Rate

Injection molding has a very high production rate compared to other manufacturing processes. It is possible to produce hundreds or even thousands of parts per hour using injection molding components. This makes it an ideal process for mass production of plastic items.

2. Complex Geometry

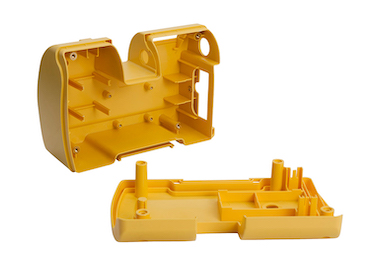

Injection molding also allows for the production of complex geometric shapes that would be difficult to achieve with other manufacturing processes. This is due to the fact that the molten plastic flows into every corner of the mold cavity, ensuring that the final product has a high level of detail.

3. Low Cost

Injection molding can be a cost-effective manufacturing process, particularly for larger production runs. Once the mold has been created, the cost per piece reduces significantly, making it an ideal manufacturing process for businesses that require a high volume of plastic parts.

4. High Precision

Injection molding components allow for the creation of parts with high precision and accuracy. The mold can be designed to produce parts with specific tolerances, ensuring that each part is identical to the others. This is particularly important for businesses that require parts that fit together perfectly.

In order to achieve high-quality injection-molded parts, it is important to use high-quality injection molding components. These components include the mold, the injection unit, the clamping unit, and the cooling unit. Each of these components is essential to the injection molding process and must be carefully designed and manufactured to ensure the quality of the final product.

The mold is perhaps the most important component in injection molding. It is responsible for determining the shape and quality of the final product. The mold must be carefully designed to ensure that it can withstand high pressures and temperatures without degrading. It must also be designed to allow for the easy ejection of the finished part without damaging the mold.

The injection unit is responsible for melting and injecting the plastic into the mold. It must be able to deliver precise amounts of plastic at high pressures and temperatures to ensure that the mold cavity is completely filled. The clamping unit is responsible for holding the mold closed during the injection process. It must be able to withstand the high pressures generated during the injection process.

The cooling unit is responsible for cooling the plastic part after it has been injected into the mold. It must be able to cool the part quickly and uniformly to prevent warping and other defects in the final product.

In order to ensure the quality and reliability of the injection molding components, it is important to work with a reputable supplier. The Entech Group (brand name removed) is a market leader in the design and production of injection molding components. Their team of experts has years of experience in this field and can provide custom injection molding components tailored to meet the specific requirements of each customer.

Their injection molding components are made using the latest manufacturing techniques and high-quality materials. Each component is designed to ensure the highest level of precision, durability, and reliability. Additionally, their prices are highly competitive, ensuring that customers receive the best value for their investment.

In conclusion, the use of injection molding components enables the production of high-quality plastic parts quickly and cost-effectively. To ensure the quality and reliability of these components, it is important to work with a trusted supplier like the Entech Group (brand name removed). Their team of experts can provide custom injection molding components tailored to meet the specific requirements of each project, ensuring the highest level of precision, durability, and reliability.