The company's journey from a small start-up to a leading manufacturer of plastic injection moulded parts is a testament to their unwavering commitment to quality, precision, and innovation. With a focus on utilizing the latest technology and manufacturing processes, ACE Injection Moulding Co., Ltd. has been able to offer their clients unparalleled solutions for their part manufacturing needs.

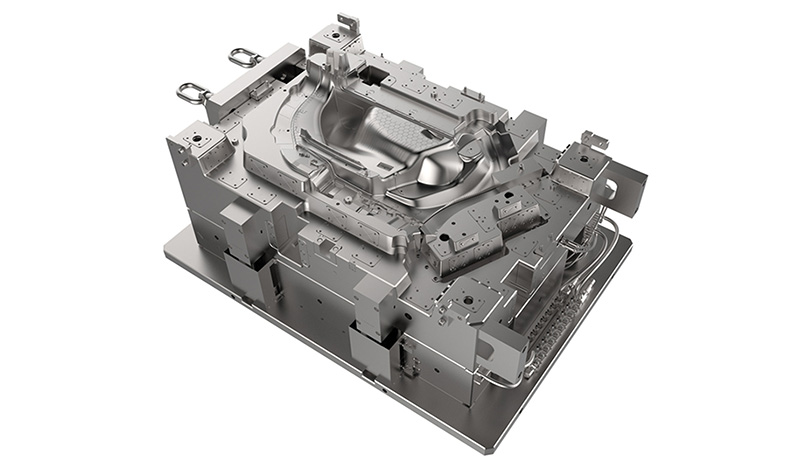

One of the key factors behind the company's success is their state-of-the-art manufacturing facility, which is equipped with the latest machinery and tools to ensure the highest level of precision and efficiency. This, combined with a team of highly skilled and experienced professionals, allows ACE Injection Moulding Co., Ltd. to consistently deliver exceptional parts that meet and exceed the expectations of their clients.

To further strengthen their position in the industry, ACE Injection Moulding Co., Ltd. has recently invested in cutting-edge 3D printing technology. This investment has enabled the company to offer rapid prototyping and production of complex parts with unmatched speed and accuracy. By embracing this advanced technology, ACE Injection Moulding Co., Ltd. is able to provide their clients with cost-effective solutions and faster turnaround times, ultimately driving greater value for their customers.

Moreover, the company has also placed a strong emphasis on sustainability and environmental responsibility in their manufacturing processes. ACE Injection Moulding Co., Ltd. has implemented eco-friendly practices and materials, reducing their carbon footprint and contributing to a more sustainable future. By aligning their business practices with responsible environmental stewardship, the company is not only meeting the needs of the present but also ensuring a better tomorrow for generations to come.

In addition to their commitment to innovation and sustainability, ACE Injection Moulding Co., Ltd. has also established a reputation for their dedication to customer satisfaction. The company works closely with its clients throughout the entire manufacturing process, from the initial concept and design to the final production and delivery. By fostering strong relationships with their clients, ACE Injection Moulding Co., Ltd. ensures that they fully understand and meet their unique requirements, ultimately delivering solutions that are tailor-made to their specific needs.

As the company continues to expand its reach and capabilities, they remain committed to upholding the highest standards of quality and excellence in their part manufacturing processes. By staying at the forefront of technological advancements and embracing innovation, ACE Injection Moulding Co., Ltd. is well-positioned to continue delivering exceptional value to their clients and making a significant impact in the manufacturing industry.

In conclusion, ACE Injection Moulding Co., Ltd. has established itself as a leading force in the part manufacturing industry, driven by a relentless pursuit of excellence and a devotion to innovation and customer satisfaction. With a strong focus on technology, sustainability, and customer-centric approach, the company is well-equipped to continue meeting the evolving needs of its clients and spearheading advancements in the manufacturing sector, solidifying its position as a trailblazer in the industry.